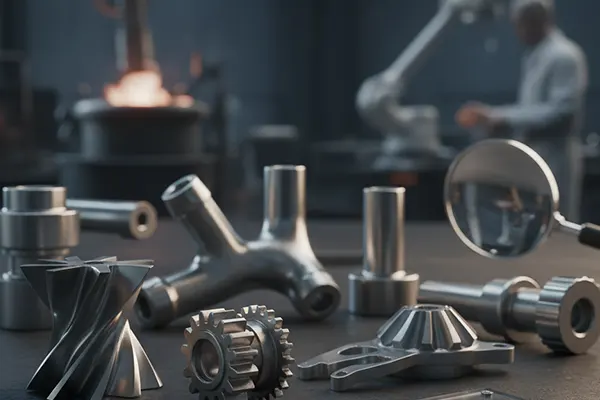

Accurate Castings For Your Industry Needs

Servicing both technical and budgetary needs, we cast high-performance, precision investment castings for your industry applications. From a single prototype to large-scale productions, we turn your most intricate metals into reliable solutions. Our global shipping network ensures you receive parts on time and in perfect condition.

Approval / Accreditation

Empowered Clients

Why Investment Casting Matters?

Investment casting, precision casting, or lost-wax casting are all methods that enable the formation of metal parts with minimal machining. It is chosen over other molding methods because the resulting castings present fine detail and incredible cast surface finishes.

A structured production system, including pattern creation, ceramic shell building, controlled melting, finishing, and inspection, supports each investment casting.

See why our investment castings stand out.

High-Performing Components

Your components are engineered to handle pressure, load, and wear through precise casting techniques that enhance durability.

Smooth and Ready To Use

Each part features a fine surface finish, reducing the need for extra machining and helping you save time in production.

Consistent Quality

Every casting is thoroughly checked at multiple stages to ensure it meets your technical and industry requirements.

High-Precision Detailing

We produce complex shapes with accuracy, from thin-walled parts to detailed 3D geometries.

Certified Alloys and Materials

You get materials that match your application needs, all backed by certification.

Accurate Dimensions

From prototype to bulk production, each component maintains uniform dimensions and tolerance consistency.

Precision Investment Castings Manufacturers: Turbocast

Turbo Cast is a certified precision investment casting manufacturer based in India, catering to aerospace, defence, medical, energy, and general engineering casting needs. We have emerged as a trusted partner for leading industries, delivering both standard and complex castings with tight tolerances and certified quality.

By having a registered and dedicated warehouse in the United States, we support faster deliveries for USA clients. Our castings are also exported to the UK, Germany, Japan, China, and several other markets. Every shipment includes required export documents and certifications to simplify customs and inspection at your end.

What Benefits Do You Get Working With Us?

Our approach focuses on collaboration and clarity to make your sourcing experience easy and predictable.

Here’s what you can expect when you partner with us:

- Transparent discussion on the process feasibility and cost

- Free consultation initially and quotation within few working days

- Low-cost solutions for both prototypes and bulk production

- Only approved prototypes proceed to full-scale manufacturing

- Regular progress updates during tooling and sampling

- In-house testing lab and quality control at every stage

- Easy traceability during shipping and documentation

- Flexible support for custom needs with on-time deliveries, domestic or global

Materials We Work With

The products we cast use various alloys that are authentically sourced. Each batch of products undergoes a strict QA process and verification, ensuring full traceability from raw material to completed casting parts.

Choose your metal for investment casting:

Stainless Steel

1.4408, 1.4581, CK3MCuN, CN7M, CK-20, CF3M, MSRR 6527, etc.

Low Alloy Steel

WCB, WCC, LCB, LCC, WC6, 1.0619, 1.6220, 1.7744.5, Gr. A2, GG20, etc.

Cobalt Alloys

Stellite-6, Stellite-12, Stellite-20, Co28Cr6Mo, etc.

Copper Alloys

Aluminum Bronze, Tin Bronze, Phosphorus Bronze, etc.

Nickel Alloys

CW12MW, CZ-100, M35-1, CW6MC, CU5MCuC, N12MV, etc.

Precipitation Hardening Steel

17-4 PH, 15-5 PH, etc.

Duplex Steel

Gr.1B (CD4MCuN), Gr.3A, Gr.4A, Gr.5A, Gr. 6A, etc.

Industries We Cater To

Our team adapts the process and alloy selection to match your needs, bringing the envisioned components to life.

Explore the industries we serve:

| Industry | Components |

|---|---|

| Aerospace & Defence | Engine parts, landing system components, structural assemblies |

| Medical & Electronics | Surgical tools, diagnostic device parts, and electronic components |

| Marine & Offshore | Hardware, impellers, fittings |

| Turbochargers & Nuclear | Turbine wheels, impellers, critical components |

| Valves & Pumps | Valve bodies, casings, bonnets, impellers |

| Automotive & Renewable Energy | Turbocharger housings, lightweight components, wind and solar parts |

| Oil & Gas | Flow-control parts, heat-resistant castings, corrosion-proof fittings |

| General Engineering & Industrial Machinery | Precision components, machine parts, and industrial equipment parts |

How Do We Process Your Casting Orders?

The processes we follow help maintain predictable lead times and consistent quality, regardless of batch size.

Here’s how a typical order progresses at Turbocast:

Assessment and Review Designs

Our team starts by understanding your casting needs. Our engineers review the drawing or CAD model that you share with in-depth detail. We rule out the process feasibility and recommend material grades and suggest process improvements.

Tooling & Wax Pattern Creation

Tooling is produced in-house for dimensional accuracy. We also use 3D-printed patterns for faster prototyping.

Ceramic Shell Formation

Wax assemblies are dipped into ceramic slurry and coated with fine sand to build strong, heat-resistant molds.

Dewaxing & Metal Pouring

Once the mold is prepared, the wax is melted out, and molten metal is poured under controlled conditions.

Finishing & Inspection

Castings are cleaned, heat-treated (if needed), and machined to specification. Each part goes through mechanical, dimensional, and NDT checks.

Packaging & Dispatch

We handle export-grade packaging, documentation, and logistics for global shipments.

If you’d like to discuss your project or request a quote, we’re happy to connect.

FAQs

Our two production units, specifically designed for aerospace and commercial casting needs, enable us to maintain certification-grade quality and offer competitive lead times for all orders.

We regularly produce prototype batches for validation and testing before volume production. So, yes, we do handle prototypes and small quantities of production.

Yes, we have in-house CNC and VMC capabilities that enable us to deliver parts that are fully machined and ready for assembly.

The delivery time ranges from 6 to 12 weeks, depending on design complexity and quantity. We supply prototypes locally within 48 hours. The delivery time is longer for global shipments. Call us to know the delivery time for your country.