Precision-Engineered And Globally Compliant Components

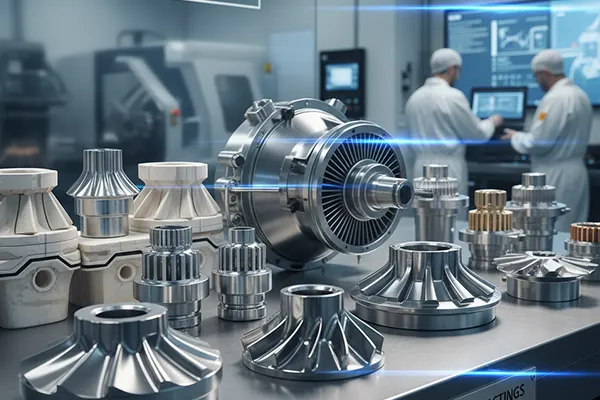

Are you looking for aerospace castings parts that reflect the same accuracy that your design demands? TurboCast delivers precision investment castings for aerospace applications, including engine parts, turbine blades, fuel system components, landing gear assemblies, and other critical components.

As one of India’s leading aerospace investment casting manufacturers, we cast your parts with zero margin for error, using our engineers' metallurgical expertise and advanced production units. Receive defect-free and high-performing castings at your location on time, ensured by our reliable logistics.

Valued Customers

Aerospace

Commercial

Approval / Accreditation

Why Choose Investment Castings For Aerospace?

Aerospace OEMs demand parts that have complex shapes, are lightweight, yet do not compromise on strength.

The investment casting process enables the achievement of components with dimensional accuracy and a net or near-net shape. Our precision investment castings help you achieve consistent part quality, thereby optimizing your total cost of ownership.

Here’s our approach to aerospace castings manufacturing:

- Reduce component weight without compromising strength or fatigue life.

- Achieve superior surface finishes and dimensional accuracy up to ±0.05 mm.

- Integrate multiple parts into one casting for efficiency and cost savings.

- Work with complex geometries ideal for turbine wheels, housings, and brackets.

- Ensure repeatability across large production runs or single prototypes.

Aerospace Components We Manufacture

Our engineers produce a wide range of aerospace-grade investment castings, fully customized to your specifications in certified production units. Our experts cast and machine-treat each component, and our in-house QA team inspects and tests it before dispatch. Receive ready-to-assemble parts that meet aerospace standards on time,defect-free.

Here are some of the components we cast:

- Jet engine components: turbine blades, stator rings, and nozzle guide vanes

- Hydraulic system parts: manifolds, valve bodies, and actuator housings

- Landing gear components: levers, links, and structural brackets

- Air and fuel system components: pumps, housings, and impeller parts

- Cabin and control components: fittings, brackets, and hardware assemblies

Materials and Alloys We Use

The alloy selection for casting aerospace parts determines the performance of your product. Our team casts parts using the correct alloy, ensuring they perform as desired under the most demanding aerospace conditions.

We source all the alloys from certified mills and undergo full chemical and mechanical property verification before casting begins, to protect your products from corrosion and other forms of damage.

Choose from our comprehensive range of aerospace-approved materials:

| Material Type | Grades | Benefits |

| Nickel-based superalloys | Inconel 718, Hastelloy, CW12MW | Corrosion-resistant, rust-free, high-strength parts |

| Stainless steels | 1.4408, 1.4581, CF3M, MSRR 6527 | High corrosion resistance and durability |

| Cobalt alloys | Stellite-6, Stellite-12 | Superior wear and heat resistance |

| Aluminum alloys | A356, A357 | Lightweight with good strength and machinability |

| Precipitation-hardening steels | 15-5 PH, 17-4 PH | High strength and toughness after heat treatment |

| Duplex & super duplex steels | — | Exceptional corrosion resistance and fatigue strength |

Note: All alloys are accompanied by certificates, test reports, and chemical analysis data, making it easy for you to maintain your compliance records.

Our Technical Capabilities

By partnering with us, you gain access to a fully integrated foundry equipped to handle your aerospace castings requirements from design to delivery. Enjoy the complete control from mold design and alloy selection to final finishing and inspection, all under one manufacturing unit.

Check out our manufacturing capabilities:

- Size range: 25 × 10 × 5 mm to 600 × 300 × 200 mm

- Weight range: 50 g to 60 kg (Steel) / 15 g to 15 kg (Aluminum)

- Installed capacity: 30 MT/month

- Rapid tooling & 3D wax printing for prototypes

- CNC and VMC machining for post-cast precision

- CAD/CAM and solidification simulation software for process optimization

Do you have a specific design in mind? We are here to help you with precision engineering.

How We Uphold Quality In Aerospace Castings

As an ISO 9001:2015 and AS9100-compliant investment casting foundry, we align with international aerospace quality standards.

We build confidence in aerospace OEMs by managing every step of production through process integrity and inspection. From wax pattern to final machining, we ensure that the process is entirely digitally recorded and validated.

See what our quality system includes:

- Spectroanalysis and metallurgical testing

- Ultrasonic and radiographic inspection (RT, UT, PT, MT)

- Dimensional and surface roughness validation

- Hydrostatic testing up to 10,000 psi

- Full batch traceability with documentation

How Our Investment Casting Process Works

Your design enters our process through a digital-first approach, ensuring zero deviation from specifications. Transparency in our processes helps reduce rework and speed up approvals.

Check out our process from CAD to certified castings:

Design Evaluation & DfM (Design For Manufacturability)

Our engineers review the geometry for casting feasibility.

Tooling & Wax Pattern Creation

Precision tools are made in-house for consistency.

Shell Building & Metal Pouring

A controlled environment ensures purity and repeatable results.

Finishing & Heat Treatment

Parts are cleaned, heat-treated, and machined to achieve the final tolerance.

Inspection & Certification

Each component is verified and shipped with full compliance reports.

Case Study

Aerospace Turbine Housing Redesign

TurboCast helped a European aerospace OEM cut costs and lead times by redesigning a billet-machined turbine housing into a single high-strength nickel alloy casting.

A leading European aerospace OEM approached TurboCast to redesign a turbine housing component that had been previously machined from billet, resulting in high costs and lengthy lead times. We re-engineered the component using investment casting with a high-strength nickel alloy, integrating three machined parts into a single casting.

Results:

Weight reduced by 18%

Machining time cut by 40%

Lead time reduced from 12 weeks to 6 weeks

Dimensional deviation reduced to under ±0.05 mm

Why Trust Turbocast For Aerospace Castings?

Established in 2015, Turbocast is India’s first indigenous investment casting foundry, specializing in ferrous and non-ferrous castings and high-precision machined components. With a global manufacturing capability, we consistently cast and deliver affordable, high-quality solutions to your location on time.

Here’s why clients across 12+ countries prefer us:

- Aerospace-grade quality with export readiness

- Global logistics with a warehouse presence in the USA

- In-house tooling and machining for complete control

- Digital transparency and real-time updates

- Proven reliability for critical and high-temperature applications