Production Facilities

Wax injection

Shell Making

Dewaxing

Machining

Heat Treatment

Melting

Press

Wax Pattern Assembly

CNC Machine Shop Facility

| Sr. No. | Machine Type | Specification (MM) | Axis | Make |

|---|---|---|---|---|

| 1 | CNC Turn Mill Center | Dia. 200 & Length 500 | 2 Axis | DMG |

| 2 | CNC Turning Center | Dia. 200 & Length 500 | 2 Axis | JYOTI |

| 3 | CNC Turning Center | Dia. 300 & Length 700 | 2 Axis | LMW |

| 4 | CNC Turning Center | Dia. 200 & Length 500 | 2 Axis | LMW |

| 5 | CNC Turning Center | Dia. 300 & Length 700 | 2 Axis | LMW |

| 6 | CNC Turning Center | Dia. 300 & Length 700 | 2 Axis | LMW |

| 7 | CNC Turning Center | Dia.400 & Length.700 | 2 Axis | LMW |

| 8 | CNC Vertical Machining Center | X=600, Y=400, Z=400 | 3 Axis | JYOTI |

| + 1 Axis (Rotary Table) | ||||

| 9 | CNC Vertical Machining Center | X=1000, Y=500, Z=500 | 3 Axis | JYOTI |

| 10 | CNC Vertical Machining Center | X=800, Y=500, Z=500 | 3 Axis | JYOTI |

| + 2 Axis (Rotary Table) | ||||

| 11 | CNC Vertical Machining Center | X=600, Y=400, Z=500 | 3 Axis | LMW |

| 12 | CNC Vertical Machining Center | X=600, Y=400, Z=400 | 3 Axis | BFW |

| + 1 Axis (Rotary Table) | ||||

| 13 | CNC Vertical Machining Center | X=800, Y=500, Z=500 | 3 Axis | JYOTI |

| + 1 Axis (Rotary Table) | ||||

| 14 | CNC Vertical Machining Center | X=800, Y=500, Z=500 | 3 Axis | JYOTI |

| + 1 Axis (Rotary Table) | ||||

| 15 | CNC Vertical Machining Center | X=800, Y=500, Z=500 | 3 Axis | JYOTI |

Special Techniques

Rapid Proto Typing (Outsource)

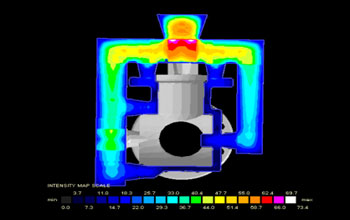

Casting Simulation (Outsource)

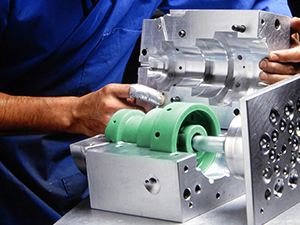

Soluble Wax Core (In House)

Ceramic Core (Outsource)

Surface Treatment (In House)

Electro Polishing

Tumble Blasting

Sand Blasting

Pickling & Passivation

Surface Treatment (Out Sourced)

Powder Coating

Phosphating

Blackening

Painting

Zinc Coating

Mirror Polishing

Anodizing