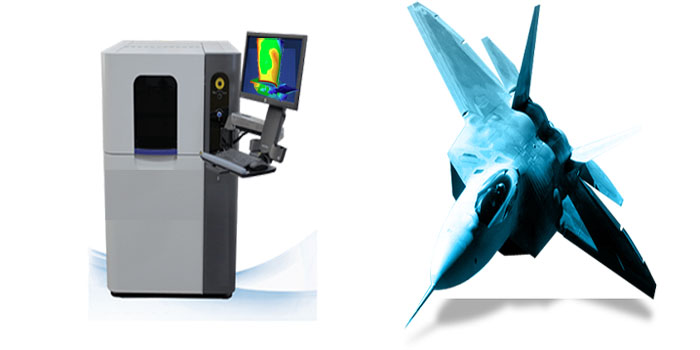

3D scanning technology is revolutionizing the Aerospace casting Company worldwide. This is widely used for inspection, modeling and measurement. Besides manufacturing of metal components, 3D scanning helps aerospace industry to get more accurate and precise components for long lasting operations.

3D laser scanners are ideal for Aerospace Investment Castings inspections as they have excellent measuring capabilities and they are able to check geometric dimensions with ease. The data can directly be sent to CAD software to manipulate, replicate or measurement. Further, 3D laser scanning process is pretty much faster and captures data points quickly. The material wastage and chances of error are just negligible.

Instead of working on few data points, 3D laser scanner captures millions of data points and remodel geometry of parts in beautiful way. Data is further sent to CAD or CAM software for final inspection and more accurate product dimensions. 3D scanning is pretty much faster when compared to other traditional quality inspection techniques in market. The process even catches small errors that cannot be read out with human eyes.

Today, there are number of manufacturers and casting industries who rely on 3D laser scanning –

The process makes sure that dimensional requirements of aerospace investment castings have been met. It provides proved documentation of most complex metal components. The process is able to optimize manufacturing process in best configurations with detailed specifications. The process reduces overall shipping defects and conducts article inspection immediately.

Measuring or inspecting complex parts with 3D laser scanner helps industries in creating most accurate CAD data that help in replicating existing parts with precision. Now casting products is no more difficult with right manufacturing technique and right technology. You just have to know about the correct manufacturing process that suits your project the most. To know more about the process, you should contact casting manufacturers or exporters right away. 3D laser scanner technology is perfect for use in aerospace tester and not manually measuring projects because they are exact measuring complicate parts like turbine blades and other aerospace parts. One of the important point 3D laser fast capturing only some pre-programmed points with CMM (coordinate measuring machine). It capture millions of data points and produce a heavy data cloud that representations the true calculation of the component. All the data to be calculated send to CAD software to be exact measured, operated and replicated.

Discuss about 3D laser scanner advantages accurate dimensions parts, client driven output, easy accurate shape, quickly procedure, reduce shipping defects. By testing and measuring complicated shape for aircraft component with a laser scanner, these industries are making the accurate CAD data they require to model legacy parts, reproduce existing components for which 3D models are no accessible and cover stringent dimensional requirements for cast and machined parts.